Article Information

The THG RKGC end-wall ventilation systems have the following characteristics:

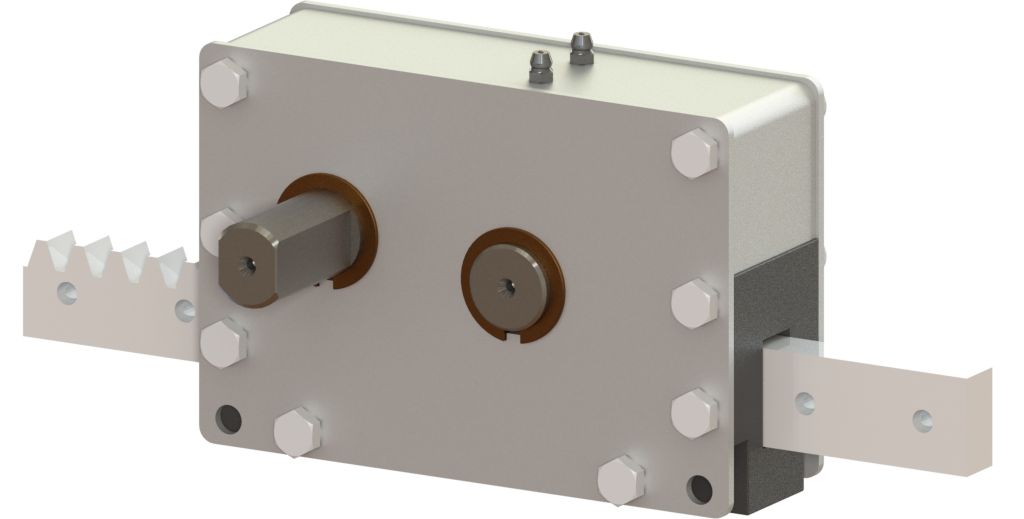

- There are three types of gear rack systems for end-wall ventilation: THG25RKGC, THG55RKGC and THG76RKGC.

- Each type is supplied complete with a rack for stroke length 750 mm, 900 mm or 1100 mm.

- Coupling to the push-pull tube by means of 27 mm or 32 mm coupling sets.

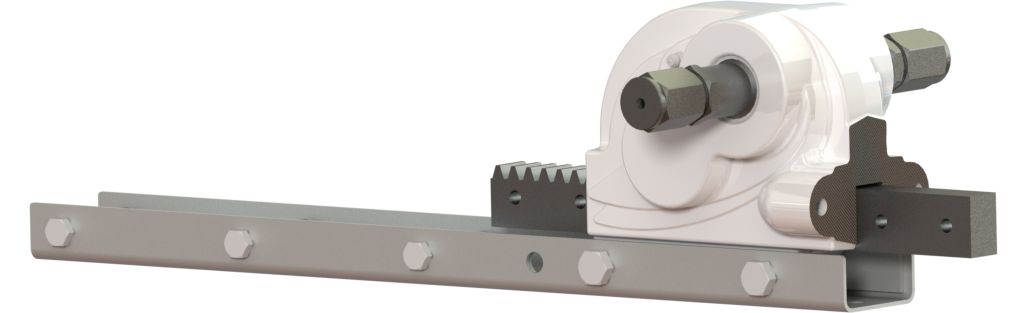

- The input shaft of the gearcase can be connected to a 1” or 5/4” drive tube by sleeve bolt chain coupling sets, shaft locking clips and/or shaft locking rings.

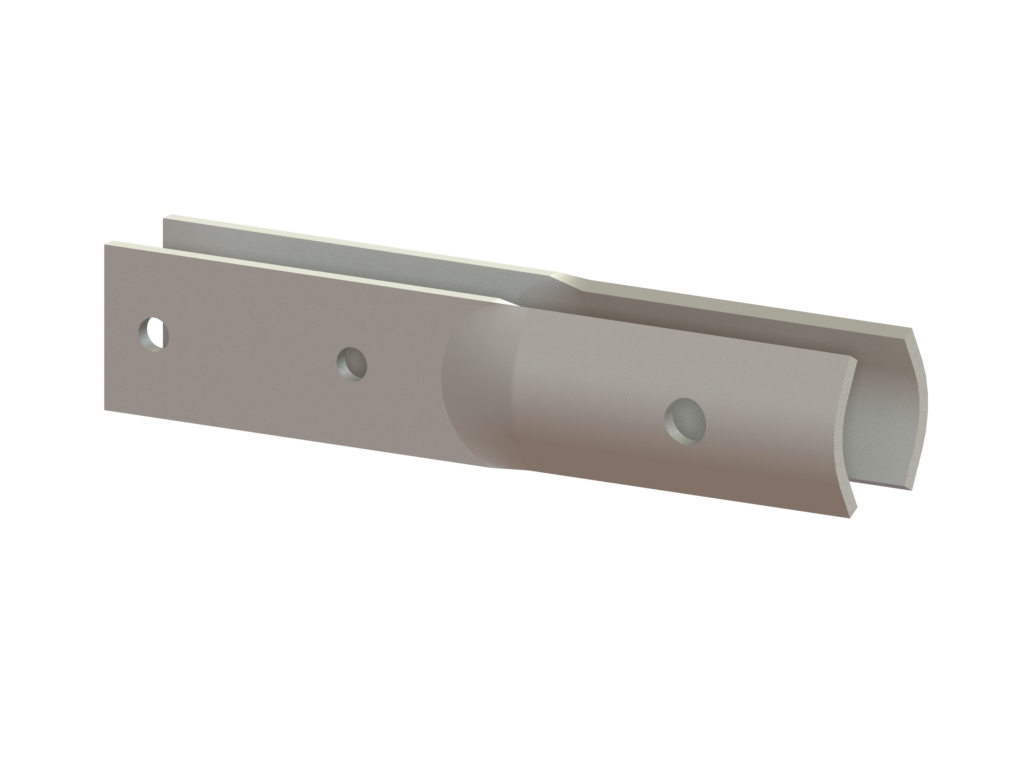

- The THG25RKGC is designed for lightly loaded systems up to 5000 N per rack and is suitable for C-profile 50 x 25 x 7 x 2.5 mm and/or U-profile 40 x 60 x 2 mm. For mounting the gearcase, 2 holes for M8 x 65 bolts must be drilled through the profile.

- The THG55RKGC is designed for medium loads up to 11,000 N per rack and is suitable for C-profile 50 x 25 x 7 x 2.5 mm. The C-profile is trimmed to 250 mm and secured in the supplied U-profile. The rack centreline is 41 mm from the inside of the C-profile.

- The THG76RKGC is designed for heavy loads up to 15,000 N per rack and is suitable for C-profile 50 x 25 x 7 x 2.5 mm. The C-profile is trimmed to 250 mm and secured in the supplied U-profile. The rack centreline is 39 mm from the inside of the C-profile.

Articles

| Article | Description | F [N] | T [Nm] | i [-] | L [mm] | S [mm] | s [mm/rev] | n [rev] | m [kg] |

| P.THG25RKGC.S0750 | THG25RKGC, L1260 S0750mm | 5000 | 32,50 | 2,760 | 1260 | 750 | 36,35 | 21 | 8,0 |

2 P.THG25RKGC.S0750 11 THG25RKGC, L1260 S0750mm 12 13 P.THG25RKGC.S0000.jpg 14 15 CAT_P.THG25RKGC.S0000_2D.gif 16 17 10 | |||||||||

| P.THG25RKGC.S0900 | THG25RKGC, L1410 S0900mm | 5000 | 32,50 | 2,760 | 1410 | 900 | 36,35 | 25 | 8,5 |

2 P.THG25RKGC.S0900 11 THG25RKGC, L1410 S0900mm 12 13 P.THG25RKGC.S0000.jpg 14 15 CAT_P.THG25RKGC.S0000_2D.gif 16 17 10 | |||||||||

| P.THG25RKGC.S1100 | THG25RKGC, L1610 S1100mm | 5000 | 32,50 | 2,760 | 1610 | 1100 | 36,35 | 31 | 9,0 |

2 P.THG25RKGC.S1100 11 THG25RKGC, L1610 S1100mm 12 13 P.THG25RKGC.S0000.jpg 14 15 CAT_P.THG25RKGC.S0000_2D.gif 16 17 10 | |||||||||

| P.THG55RKGC.1.S0750 | THG55RKGC, L1260 S0750mm | 11000 | 65,00 | 3,125 | 1260 | 750 | 36,19 | 21 | 10,1 |

2 P.THG55RKGC.1.S0750 11 THG55RKGC, L1260 S0750mm 12 13 P.THG55RKGC.1.S0000.jpg 14 15 CAT_P.THG55RKGC.1.S0000_2D.gif 16 17 10 | |||||||||

| P.THG55RKGC.1.S0900 | THG55RKGC, L1410 S0900mm | 11000 | 65,00 | 3,125 | 1410 | 900 | 36,19 | 25 | 10,6 |

2 P.THG55RKGC.1.S0900 11 THG55RKGC, L1410 S0900mm 12 13 P.THG55RKGC.1.S0000.jpg 14 15 CAT_P.THG55RKGC.1.S0000_2D.gif 16 17 10 | |||||||||

| P.THG55RKGC.1.S1100 | THG55RKGC, L1610 S1100mm | 11000 | 65,00 | 3,125 | 1610 | 1100 | 36,19 | 31 | 11,6 |

2 P.THG55RKGC.1.S1100 11 THG55RKGC, L1610 S1100mm 12 13 P.THG55RKGC.1.S0000.jpg 14 15 CAT_P.THG55RKGC.1.S0000_2D.gif 16 17 10 | |||||||||

| P.THG76RKGC.1.S0750 | THG76RKGC 15kN m4, L1250 S0750mm | 15000 | 60,50 | 6,000 | 1250 | 750 | 23 | 33 | 14,1 |

2 P.THG76RKGC.1.S0750 11 THG76RKGC 15kN m4, L1250 S0750mm 12 13 P.THG76RKGC.1.S0000.jpg 14 15 CAT_P.THG76RKGC.1.S0000_2D.gif 16 17 10 | |||||||||

| P.THG76RKGC.1.S0900 | THG76RKGC 15kN m4, L1400 S0900mm | 15000 | 60,50 | 6,000 | 1400 | 900 | 23 | 39 | 14,9 |

2 P.THG76RKGC.1.S0900 11 THG76RKGC 15kN m4, L1400 S0900mm 12 13 P.THG76RKGC.1.S0000.jpg 14 15 CAT_P.THG76RKGC.1.S0000_2D.gif 16 17 10 | |||||||||

| P.THG76RKGC.1.S1050 | THG76RKGC 15kN m4, L1550 S1050mm | 15000 | 60,50 | 6,000 | 1550 | 1050 | 23 | 48 | 15,9 |

2 P.THG76RKGC.1.S1050 11 THG76RKGC 15kN m4, L1550 S1050mm 12 13 P.THG76RKGC.1.S0000.jpg 14 15 CAT_P.THG76RKGC.1.S0000_2D.gif 16 17 10 |

General Information

An optimal climate in the greenhouse is important for maximising yield. Balanced natural ventilation of the various sections in the greenhouse contributes to this. For this we offer a wide range of gear rack systems for Venlo greenhouses. These systems are coupled to the push-pull tubes of the ventilation system, which opens or closes the ventilation windows. We distinguish between various options.

THG truss-rail ventilation column mounting

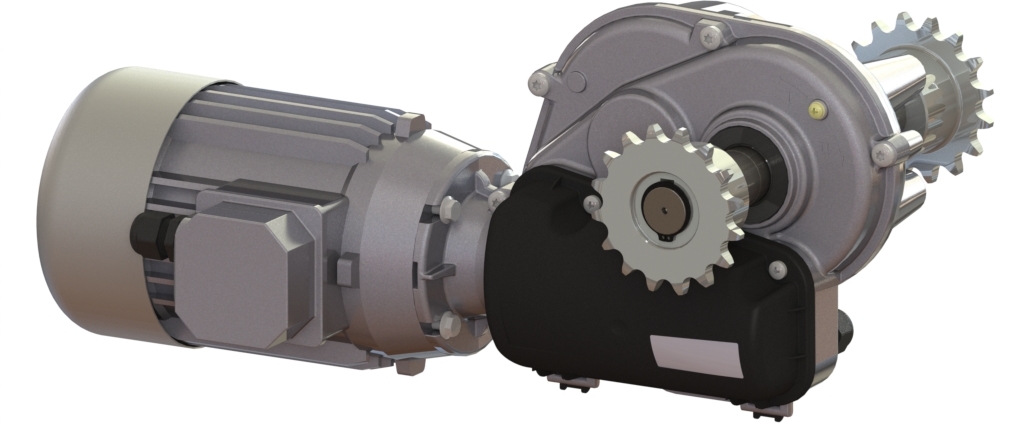

The THG RK series is designed for mounting against the column. The systems are fitted around the column, as it were, and then clamped with bolts. A GW motor gearbox drives a shaft that is connected to the rack box and moves the rack. The gear rack then drives a push-pull tube which opens and closes windows. The rack box is equipped with an integrated 5/4" bearing plate for the counter air tube.

Advantages of column mounting

- Maximum light yield, minimum shadow.

- Very easy to install on the column.

- Ideal force transfer on the column.

- Suitable for prefabrication of drive shafts.

- Particularly suitable for lighter ventilation windows.

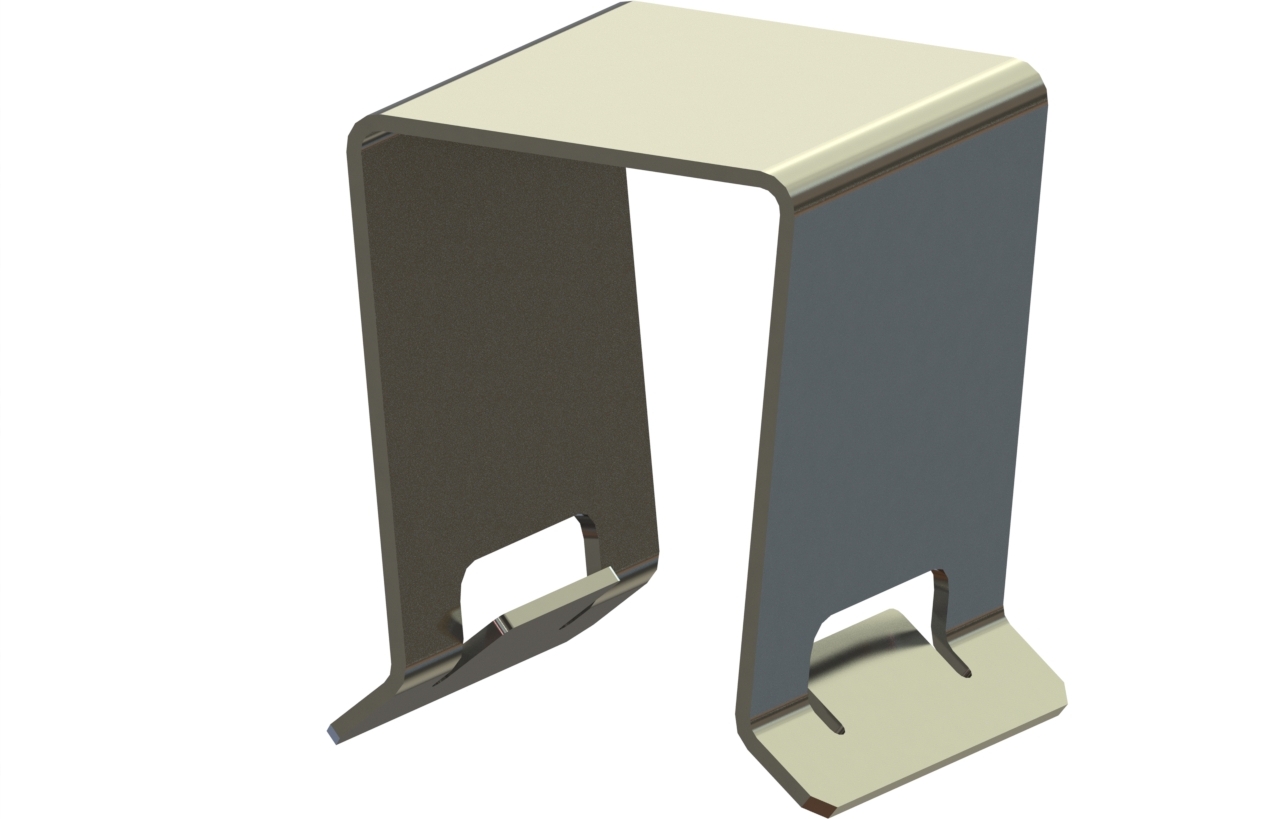

THG RKGC end-wall ventilation

When it comes to ventilation, it is important that the entire section is optimally ventilated and that there are no zones where the conditions are far from optimal. Venlo greenhouses and truss-rail ventilation systems have ventilation windows centrally located above the truss. This creates an area that is less well ventilated. Ventilation of the end section next to the end wall is important for optimal climate control. The THG RKGC is a Rack box specially developed for driving end-wall ventilation windows. The rack box is driven by a GW motor gearbox. The gear rack drives the push-pull tube. Standard delivery takes place by racks.

THG truss-rail ventilation truss mounting

An alternative to mounting around the column is to mount gear racks on the truss. For this we offer the THGR drive, a powerful and low-maintenance drive for ventilation in Venlo greenhouses. A GW motor gearbox drives a shaft that is connected to the rack box and moves the rack. The gear rack then drives a push-pull tube which opens and closes windows. The drive shafts are supported by glide bearing plates which are mounted on the trusses.

THG RGC end-wall ventilation

The THG RGC is a rack box and is intended for driving end-wall ventilation windows. The rack box is driven by a GW motor gearbox. The gear rack drives the push-pull tube. Standard delivery takes place using racks.

De Gier Drive Systems

+ 31 174 29 20 89